A Short History of the Dixon Pencil Company of Canada

- 1931 - The Dixon Pencil Company of Canada was established in Newmarket, Ontario. The company purchased the existing Cane's pencil factory at 531 Davis Drive . The Cane's factory has begun producing pencils in 1920.

- 1977 - Dixon purchases the Eberhard Faber factory in Acton Vale, QC. It is mainly used to manufacture erasers (such as Dixon branded Pink Pearl erasers).

- Sept. 30, 1990 - The Dixon factory in Newmarket is closed and soon thereafter, the building was demolished. (source) The last Ticonderoga Pencil rolled off the line on July 20, 1990. (source). Erasers and rubber bands continue to be manufactured at the Dixon factory in Acton Vale.

- 2005 - Dixon Pencil is bought by Fila. The Dixon manufacturing facility in Acton Vale, that was originally owned by Eberhard Faber, is closed later in the year.

Advertising

|

Dixon packaging in the U.S. often included images of Ethan Allen, especially on Ticonderoga pencils. Ethan Allen was instrumental in the capture of Fort Ticonderoga early in the Revolutionary War from the fort's small British garrison.

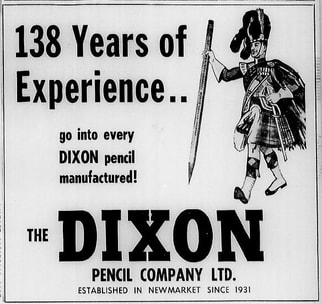

In Canada, packaging instead often contained an image of a soldier in traditional Scottish military attire. Check out the Pencil Talk website for another ad. |

News Articles

Newmarket Era, 20 Feb 1931, page 3

Newmarket Pencil Factory to Reopen in 30 Days

Newmarket Pencil Factory to Reopen in 30 Days

Newmarket Era and Express, 14 January 1960, page 1

Pencils Pointed Way to Prosperity

Old Joe Dixon deserves a warm place in the hearts of many townsfolk. Today they earn their living through the original dogged persistence of this ingenious inventor who in turn was ship's boy, prankster, chemist, printer, woodcarver and bibliographer.

Next week sees the anniversary of his birth in the little town of Marblehead, Mass., in 1799, where his father, a shipowner had visions of his son becoming a physician.

Fortunately for the world and Newmarket, young Joe's interest in the healing profession waned. Instead his agile mind turned to solving problems and improving processes in a wide field, covering such diverse achievements as a file cutting machine (in those days files and all been made by hand), the development of photo-lithography, years ahead of its practical usefulness, the invention of new dyes and inks which made the counterfeiting of bank notes the virtual impossibility it is today.

He also developed, accidentally, stove polish and with the money earned from that venture went on to make graphite crucibles for steel making processes which were destined to become technical and financial successes and the foundation of the Dixon enterprises.

Early Struggles

Dixon, who has been compared with Edison for his contributions to the betterment of mankind, is best known as the father of the modern pencil. Prior to his tinkering with graphite and clay, the few people who did write resorted to the quill and ink, at best a messy and impracticable business. Alternatively, there was an imported excuse for a pencil available but which was both primitive and expensive.

Joseph Dixon first became interested in the idea of a new and better writing aid when he noticed the base quantities of graphite ore dumped from his father's ships. The material was brought from the East as ballast in the sailing vessels, being both heavy and cheap.

To the young inventor here was an ideal substance for his creative imagination.

Those early years of experimentation to fuse clay and graphite satisfactorily and insert the completed compound into pieces of grooved wood were frustrating. Success did not come easily and for many years Joseph Dixon's other interests supported the infant pencil industry.

The Present Day

However, those struggling early years are now past and have become part of the heritage of Canada's leading pencil manufacturer. To the management and staff of the Dixon Pencil Co. on Davis Drive, a subsidiary of the giant Joseph Dixon Crucible Co. of Jersey City, pencils are big business. And to the customer, pencils are an expendable necessity.

Coming to Newmarket in 1931 the company moved into the massive 93,000 square feet building which it continues to occupy today and from which an estimated 18 million pencils are turned out ... every year ... more than enough to allow one each to every man, woman and child in the Dominion.

Pencils, by no means the only product of the firm, are manufactured with as many as 147 variations and each basic color is available from a choice of 28 pastel shades.

The graphite, or "lead" as it is commonly called, is compounded from a secret formula jealously guarded for its qualities of strength and durability and is trucked in from an affiliate in the U.S. ready to be inserted automatically into the wooden shafts.

With the American parent company, Dixon's in Newmarket has become the world's largest manufacturer of graphite and, apart from the native ore, imports thousands of tons from Ceylon, Madagascar and Mexico.

Proud Boast

Headed by J. S. Law, president of the company for the past five years, Dixon salesmen cover territories from coast to coast, meeting their wholesale customers with the inclusion of good will visits to schools and offices. Those efforts are all channelled to sustain the company's boast of 52 weeks work for every year for their 62 employees, the majority of whom live in town.

The boast is justified and one of which they are proud. The loyalty of their workers is illustrated by the length of service many have to their credit and the management's reluctance to lay-off personnel. Their turnover in staff for concerns of comparable size is perhaps the lowest in the country.

Now a public limited liability company, their stock is owned around the world but with a large share held by the employees themselves. This is but another mark of confidence in a company which has failed to declare its quarterly dividend only twice in its 131 years history. A remarkable record of stability and modest prosperity through the vagaries of economic climate and recessions.

This past week, representatives of the Dixon Pencils Co. gathered in town at their annual sales conference to hear Vice-President H. F. Eaton predict further solid progress and the continued introduction of new methods to meet changing conditions. Added Treasure F. T. Courtney, "We've certainly come a long way since old Joe's day."

Pencils Pointed Way to Prosperity

Old Joe Dixon deserves a warm place in the hearts of many townsfolk. Today they earn their living through the original dogged persistence of this ingenious inventor who in turn was ship's boy, prankster, chemist, printer, woodcarver and bibliographer.

Next week sees the anniversary of his birth in the little town of Marblehead, Mass., in 1799, where his father, a shipowner had visions of his son becoming a physician.

Fortunately for the world and Newmarket, young Joe's interest in the healing profession waned. Instead his agile mind turned to solving problems and improving processes in a wide field, covering such diverse achievements as a file cutting machine (in those days files and all been made by hand), the development of photo-lithography, years ahead of its practical usefulness, the invention of new dyes and inks which made the counterfeiting of bank notes the virtual impossibility it is today.

He also developed, accidentally, stove polish and with the money earned from that venture went on to make graphite crucibles for steel making processes which were destined to become technical and financial successes and the foundation of the Dixon enterprises.

Early Struggles

Dixon, who has been compared with Edison for his contributions to the betterment of mankind, is best known as the father of the modern pencil. Prior to his tinkering with graphite and clay, the few people who did write resorted to the quill and ink, at best a messy and impracticable business. Alternatively, there was an imported excuse for a pencil available but which was both primitive and expensive.

Joseph Dixon first became interested in the idea of a new and better writing aid when he noticed the base quantities of graphite ore dumped from his father's ships. The material was brought from the East as ballast in the sailing vessels, being both heavy and cheap.

To the young inventor here was an ideal substance for his creative imagination.

Those early years of experimentation to fuse clay and graphite satisfactorily and insert the completed compound into pieces of grooved wood were frustrating. Success did not come easily and for many years Joseph Dixon's other interests supported the infant pencil industry.

The Present Day

However, those struggling early years are now past and have become part of the heritage of Canada's leading pencil manufacturer. To the management and staff of the Dixon Pencil Co. on Davis Drive, a subsidiary of the giant Joseph Dixon Crucible Co. of Jersey City, pencils are big business. And to the customer, pencils are an expendable necessity.

Coming to Newmarket in 1931 the company moved into the massive 93,000 square feet building which it continues to occupy today and from which an estimated 18 million pencils are turned out ... every year ... more than enough to allow one each to every man, woman and child in the Dominion.

Pencils, by no means the only product of the firm, are manufactured with as many as 147 variations and each basic color is available from a choice of 28 pastel shades.

The graphite, or "lead" as it is commonly called, is compounded from a secret formula jealously guarded for its qualities of strength and durability and is trucked in from an affiliate in the U.S. ready to be inserted automatically into the wooden shafts.

With the American parent company, Dixon's in Newmarket has become the world's largest manufacturer of graphite and, apart from the native ore, imports thousands of tons from Ceylon, Madagascar and Mexico.

Proud Boast

Headed by J. S. Law, president of the company for the past five years, Dixon salesmen cover territories from coast to coast, meeting their wholesale customers with the inclusion of good will visits to schools and offices. Those efforts are all channelled to sustain the company's boast of 52 weeks work for every year for their 62 employees, the majority of whom live in town.

The boast is justified and one of which they are proud. The loyalty of their workers is illustrated by the length of service many have to their credit and the management's reluctance to lay-off personnel. Their turnover in staff for concerns of comparable size is perhaps the lowest in the country.

Now a public limited liability company, their stock is owned around the world but with a large share held by the employees themselves. This is but another mark of confidence in a company which has failed to declare its quarterly dividend only twice in its 131 years history. A remarkable record of stability and modest prosperity through the vagaries of economic climate and recessions.

This past week, representatives of the Dixon Pencils Co. gathered in town at their annual sales conference to hear Vice-President H. F. Eaton predict further solid progress and the continued introduction of new methods to meet changing conditions. Added Treasure F. T. Courtney, "We've certainly come a long way since old Joe's day."

Newmarket Era and Express, 26 June 1963

Dixon Pencils Are Recognized as Fine Product of Newmarket

Clay, graphite, plumbago, California Cedar and lacquer are recognized requisites in the making of a pencil, but to produce a quality product in the lead pencil field requires something else.

Pertinacity, the desire to produce a top ranking product, the best equipment available, a qualified sales staff, all coupled with the physical components have placed Dixon Pencil Company among the leaders.

Add in all of this the policy of Canadian Made for use in Canada and it becomes quite understandable why the name Dixon is readily recognized and accepted in the various levels of commerce from the largest industry to the smallest office, and even in the housewife's domain, the kitchen.

Dixon and Newmarket are synonymous. Since 1931 the company and its employees have contributed in many ways to the well-being and development of the town. When Dixon pencils are bought in Halifax, Montreal, Saskatoon and Vancouver, very few of the purchasers fail to know that they were produced in Newmarket.

Established in Canada (Newmarket) in 1931, the local company has produced wood en-cased pencils up to 20-million annually. This is definitely an achievement of some note.

The oft-regarded "lowly lead pencil" has held its place in all phases of Canadian life. Without it, no vital production is started without its service on the drawing board.

If the pencil were to be suddenly removed from our society, only then would its true value be realized. There is no doubt the pencil is here to stay, notwithstanding the growth in popularity of other writing tools.

Have Many Lines

To say that Dixon's produce pencils is hardly adequate, for the variety is both great and diversified. There are 17 different degrees of graphite leads, each compounded for a specific purpose in some special field. Similarly, there are upwards of 40 coloring leads in use, plus marking pencils and a full range of lumber crayons. The latter is a most popular item in the lumber business from tree-cutting in the forest to the time the finished board is started in the local building supply yard.

In addition to the regular lines retailed, Dixon has a solid sales background in "specials". Those include imprinted pencils, those made specifically for government agencies and schools, railroads and others. In this field repeat orders are conspicuous by their frequency.

The oldest pencil company in Canada has kept pace with demand and in so doing, built up a clientele second to none and a prestige among the trade of which all associated with Dixon Pencil Company may be proud.

Growth of the company is reflected in the number employed at Newmarket, presently 55 and at sales offices situated at St. John, New Brunswick; St. Johns, Newfoundland; Quebec City, Montreal, Toronto, Ottawa, London, Winnipeg and Vancouver.

What of production at Newmarket? Raw lead, a compounding of clay, graphite and plumbago, is brought in from the United States in boxes containing thousands of the long thin strips. This is the true core of the ultimate pencil.

Slabs of California cedar, are grooved in "house" the core, are glued together and later machined to form the rough, hexagon or round shape of the pencil. Cut into individual pencils, they are brought to finished size, sanded smoothly and coated with lacquer. Thus the pencil takes shape.

The application of seven further coats of lacquer, in any color required, followed by trimming and the pencil is ready for the imprinting of the name and quality of lead. Metal tips to hold the eraser are applied by a special process which eliminates the "crimping" treatment common to most other lines of pencils.

Inspection, sorting, boxing or special packaging is the forerunner of the trip to the stockroom where each brand name and lead grade of pencil has its appointed storage area. Because demand for Dixon pencils remains constant, the flow of stock seems to be unending.

Company Keeps Pace

As mentioned earlier, Dixon has kept pace with demand, and to do so has added "related" items to their to their inventory. Tempura colors, both dry and wet, educational lines such as several grades of colored crayons and chalks, beginners pencils, ball point pens and several other items are stocked to place Dixon Pencil Company in a very choice position in the consumer market.

Production at its best, resulting in quality products, good sales representatives, service to customers, are the qualities which make the "Made in Canada" tag mean a great deal to the company, its employees, the town in which they live and also in the ultimate user of a Dixon Pencil.

Donald Tait is vice president and general manager of Canadian operation. Gil H. Smith is vice president in charge of sales, Ivan Ruddock is the plant superintendent.

Dixon Pencils Are Recognized as Fine Product of Newmarket

Clay, graphite, plumbago, California Cedar and lacquer are recognized requisites in the making of a pencil, but to produce a quality product in the lead pencil field requires something else.

Pertinacity, the desire to produce a top ranking product, the best equipment available, a qualified sales staff, all coupled with the physical components have placed Dixon Pencil Company among the leaders.

Add in all of this the policy of Canadian Made for use in Canada and it becomes quite understandable why the name Dixon is readily recognized and accepted in the various levels of commerce from the largest industry to the smallest office, and even in the housewife's domain, the kitchen.

Dixon and Newmarket are synonymous. Since 1931 the company and its employees have contributed in many ways to the well-being and development of the town. When Dixon pencils are bought in Halifax, Montreal, Saskatoon and Vancouver, very few of the purchasers fail to know that they were produced in Newmarket.

Established in Canada (Newmarket) in 1931, the local company has produced wood en-cased pencils up to 20-million annually. This is definitely an achievement of some note.

The oft-regarded "lowly lead pencil" has held its place in all phases of Canadian life. Without it, no vital production is started without its service on the drawing board.

If the pencil were to be suddenly removed from our society, only then would its true value be realized. There is no doubt the pencil is here to stay, notwithstanding the growth in popularity of other writing tools.

Have Many Lines

To say that Dixon's produce pencils is hardly adequate, for the variety is both great and diversified. There are 17 different degrees of graphite leads, each compounded for a specific purpose in some special field. Similarly, there are upwards of 40 coloring leads in use, plus marking pencils and a full range of lumber crayons. The latter is a most popular item in the lumber business from tree-cutting in the forest to the time the finished board is started in the local building supply yard.

In addition to the regular lines retailed, Dixon has a solid sales background in "specials". Those include imprinted pencils, those made specifically for government agencies and schools, railroads and others. In this field repeat orders are conspicuous by their frequency.

The oldest pencil company in Canada has kept pace with demand and in so doing, built up a clientele second to none and a prestige among the trade of which all associated with Dixon Pencil Company may be proud.

Growth of the company is reflected in the number employed at Newmarket, presently 55 and at sales offices situated at St. John, New Brunswick; St. Johns, Newfoundland; Quebec City, Montreal, Toronto, Ottawa, London, Winnipeg and Vancouver.

What of production at Newmarket? Raw lead, a compounding of clay, graphite and plumbago, is brought in from the United States in boxes containing thousands of the long thin strips. This is the true core of the ultimate pencil.

Slabs of California cedar, are grooved in "house" the core, are glued together and later machined to form the rough, hexagon or round shape of the pencil. Cut into individual pencils, they are brought to finished size, sanded smoothly and coated with lacquer. Thus the pencil takes shape.

The application of seven further coats of lacquer, in any color required, followed by trimming and the pencil is ready for the imprinting of the name and quality of lead. Metal tips to hold the eraser are applied by a special process which eliminates the "crimping" treatment common to most other lines of pencils.

Inspection, sorting, boxing or special packaging is the forerunner of the trip to the stockroom where each brand name and lead grade of pencil has its appointed storage area. Because demand for Dixon pencils remains constant, the flow of stock seems to be unending.

Company Keeps Pace

As mentioned earlier, Dixon has kept pace with demand, and to do so has added "related" items to their to their inventory. Tempura colors, both dry and wet, educational lines such as several grades of colored crayons and chalks, beginners pencils, ball point pens and several other items are stocked to place Dixon Pencil Company in a very choice position in the consumer market.

Production at its best, resulting in quality products, good sales representatives, service to customers, are the qualities which make the "Made in Canada" tag mean a great deal to the company, its employees, the town in which they live and also in the ultimate user of a Dixon Pencil.

Donald Tait is vice president and general manager of Canadian operation. Gil H. Smith is vice president in charge of sales, Ivan Ruddock is the plant superintendent.